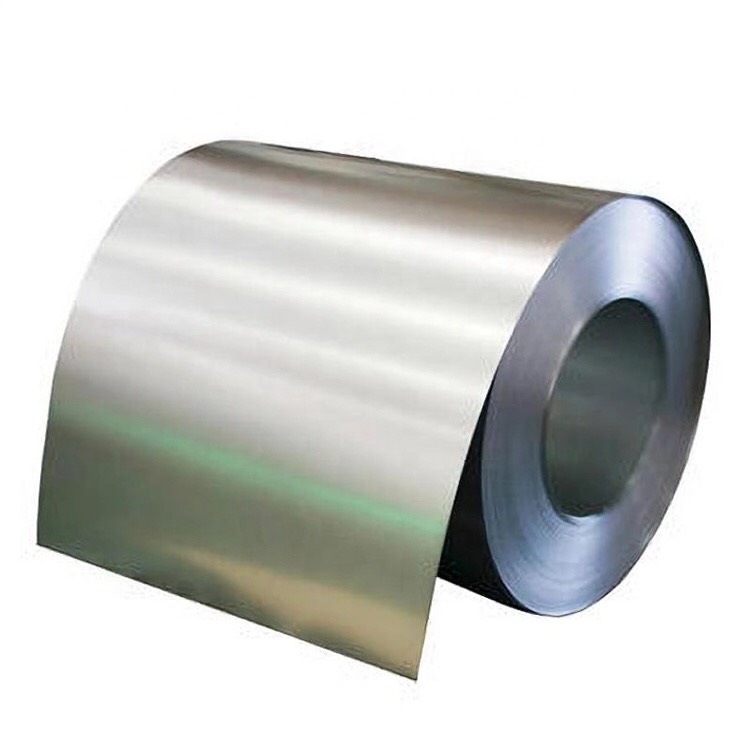

SPCG Galvanized Steel Coil Features

1. Galvanized steel coil is widely used in various environments and has a long anti-corrosion life. The anti-corrosion life is different in different environments.

2. The processing cost is low, and the anti-corrosion cost of galvanized steel coil is lower than other paint coatings.

3. Durable, in the suburban environment, the standard galvanized anti-corrosion layer does not need to be repaired and can be maintained for more than 50 years. In cities or offshore areas, the standard galvanized anti-corrosion coating can be maintained for 20 years without repairs.

4. Good reliability. The galvanized layer and the steel are metallurgically combined and become part of the rigid surface, so the durability of the coating is relatively reliable.

5. The coating has strong toughness, and the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

6. Integrity protection: All parts of the plated parts can be galvanized, even in recesses, sharp corners and hidden places can be fully protected.

7. It saves time and effort. The galvanizing construction speed is faster than other coating construction methods, which can avoid the time required for on-site painting after installation.

SPCG Galvanized Steel Coil Equivalent Material

| Grade | Euronorm | China GB | Japanese JIS | US ASTM | German | ||

| EN10130-2006 | GB/T 5213-2008 | JISG3141-2005 | ASTMA1008-2005 | Q/SGZGS 324.3-2011 | |||

| SPCG | DC06 | DC06 | SPCG | EDDS | St16 | ||

SPCG Galvanized Steel Coil Standard Specification

| Thickness | 0.12~2.5mm | ||||||

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc | ||||||

| Length | 1000-6000 or Since the custom | ||||||

| Surface | Normal (uneven) spangle/ Skinpassed spangle/ Regular spangle / Minimized spangles | ||||||

| Finish | |||||||

| Form | coils, Foils, Rolls, Plain coil, Shim coil, Perforated coil, Chequered coil, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

||||||

SPCG Galvanized Steel Coil Metal Content

| Grade | Element | C | Mn | P | S |

| SPCG | Min. | – | – | – | – |

| Max. | 0.2 | 0.25 | 0.02 | 0.02 |

- Tensile strength :≥270 MPa

- Yield strength :≤190 MPa

- Elongation :32~42%