What are the benefits of aluminum recycling?

As one of the world’s most environmentally friendly materials, aluminum is a valuable metal widely recognized for its environmental benefits and positive economic impact. According to the Aluminum Association, aluminum is the most recyclable of all materials, with discarded aluminum being more valuable than any other item in the recycling bin.

With growing public awareness and calls to improve manufacturing processes by environmental groups and activists, aluminum certainly has an edge in the fight against the world’s environmental burden.

How Is Aluminum Recycled?

How Is Aluminum Recycled?

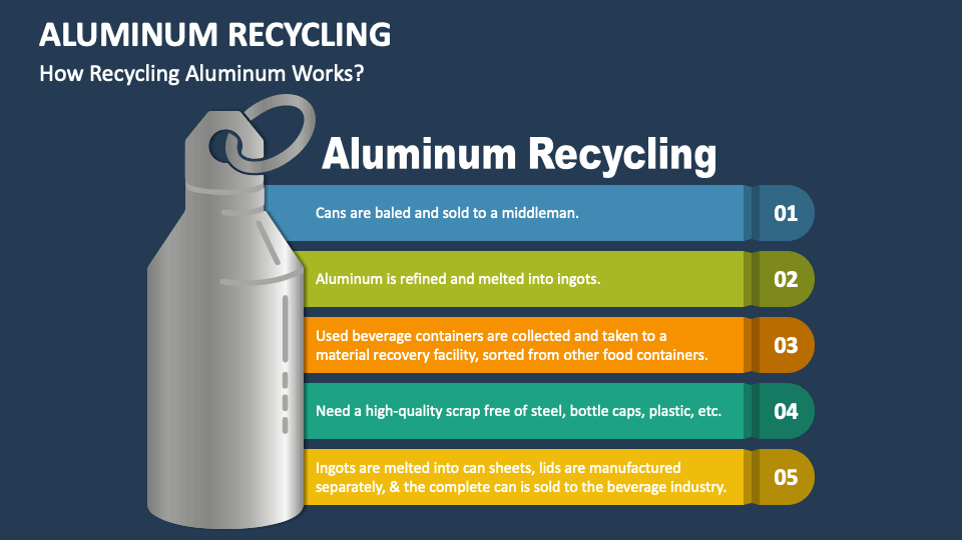

Aluminum undergoes several recycling programs for different purposes. One of the most commonly recognized programs is curbside and city. In these recycling programs, waste items such as beverage cans, aluminum cans, aluminum foil materials, aluminum baking trays and baking molds are included in the recycling process.

The aluminum industry, undoubtedly a large and thriving industry in the country, is known to actively support various initiatives and programs related to recycling. One of these programs is the Recycling Partnership — a program that aims to increase participation in curbside recycling programs.

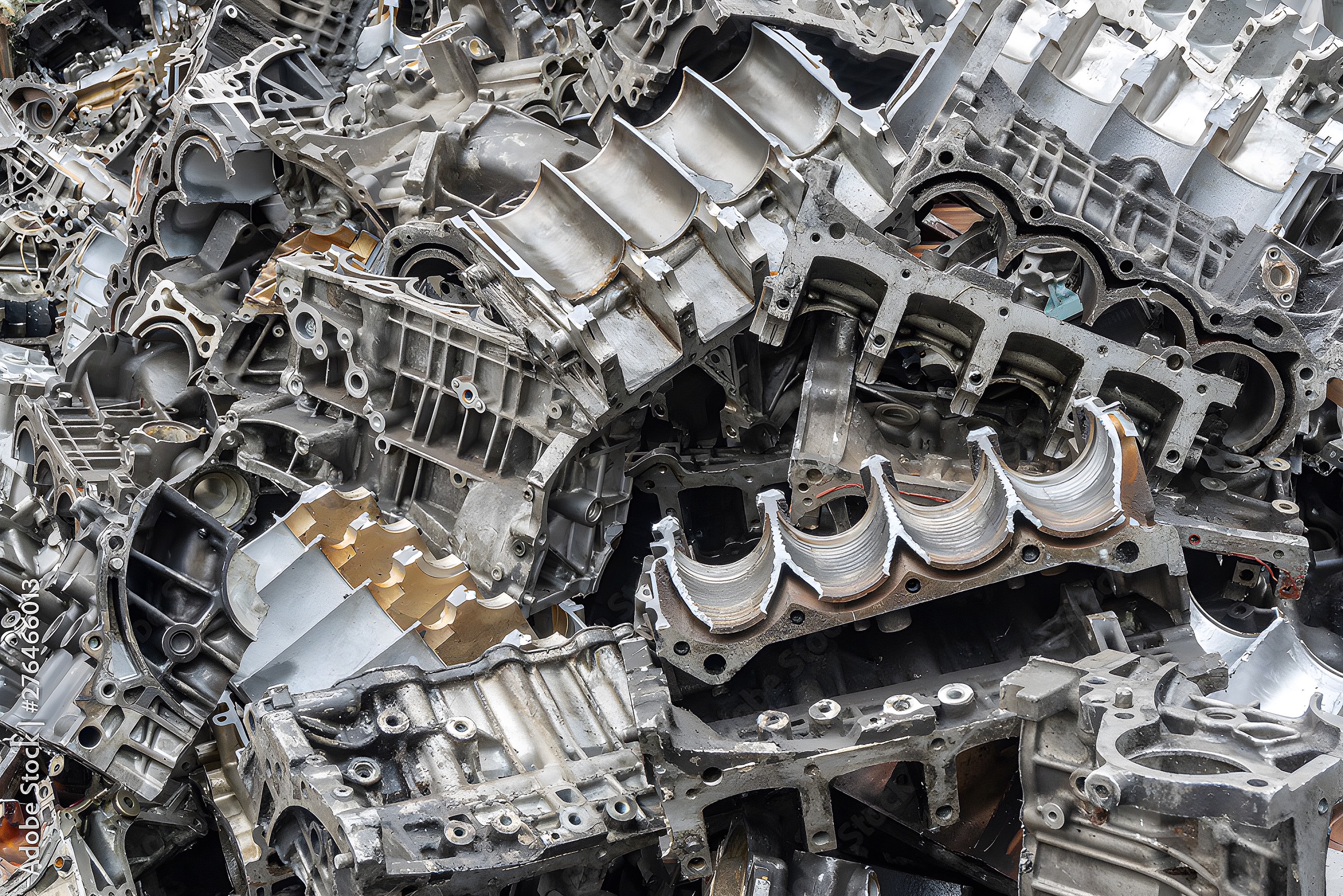

Did you know that more than 90 percent of the aluminum used to create and make automotive parts is recycled at the end of its life? These items are often sent to various aluminum recyclers for aluminum recycling or the act of smelting them in a secondary production process.

The Benefits Of Recycling Aluminum

From your favorite beverage container to other forms of packaging, aluminum provides a number of products after being put into the recycling process. Because of the material’s value and benefits, it has cemented its position as one of the most recycled metals and materials in the United States.

When compared to other materials, manufacturers and recyclers can count on aluminum more than paying for their own recycling — this applies to both consumer and waste streams. industry. This is as demand for the material continues to grow, a significant growth that can be attributed to the economic and environmental performance of the material — saving more than 90 percent of the energy required when producing new metals. .

- Economical sustainability – Aluminum is considered by many to be a great choice to promote good recycling practices but it also has a good value for economic sustainability. This is because it is one of the only materials that pay more for its own recycling. This applies to both consumer and industrial waste streams. Through this recycling process, businesses can quickly boost their production and operations. For example, in the beverage container industry, aluminum contains 3 times more recycled content (73%) than any beverage container (23% glass and 3% plastic).

- Increase of job opportunities – Due to the sustainable and beneficial nature of aluminum, it has also directly impacted the size and economic impact of the industry as a whole. According to figures provided by the Aluminum Association, 161,000 workers are directly employed in the industry. For each job in this aluminum industry, there are about 3.3 job openings created elsewhere. Simply put, the sustainability of aluminum is driving competitive and profitable business advantages while creating various product development opportunities that enable businesses to grow and create more jobs. than.

- Improved energy efficiency and standards – Innovations using aluminum are not limited to different containers and materials but also in the infrastructure sector. The Metropolitan Area’s East End Building complex, located in Sacramento, California, has been awarded the state’s first LEED certification for the buildings. This certification was awarded in recognition of the structure’s high performance, non-reflective aluminum curtain wall. This aluminum curtain wall allows the building to naturally cool the interior, making room for the building’s deserved distinction in being at the forefront of energy and environmental design.

- Long-term sustainability – Another proof that aluminum is a valuable recyclable is its time-tested reputation for long-term sustainability. The material was first introduced into the mainstream product market in the United States in the early 1900s. This was primarily done through the aluminum foil and packaging industry. To date, almost 75% of the aluminum ever produced is still intact and in use.

- Industry success – For the aluminum industry, recycling is an important part of every business. In the United States and Canada alone, the aluminum industry can recycle more than 5 million tons of aluminum annually. Most of these recycled products go back to direct supply to the North American market. Since producing recycled aluminum is 92% more energy efficient than producing new aluminum, the industry can achieve dual benefits for business and the environment.

The Bottomline

The growing trend of using recycled aluminum for a number of products — whether it’s aluminum canned water, packaging and containers — is a win for environmental and economic sustainability. With the myriad benefits and values associated with the recycling, production and use of aluminum materials, the industry can move closer to a more fuel- and energy-efficient future.

Aluminum Recycle Process

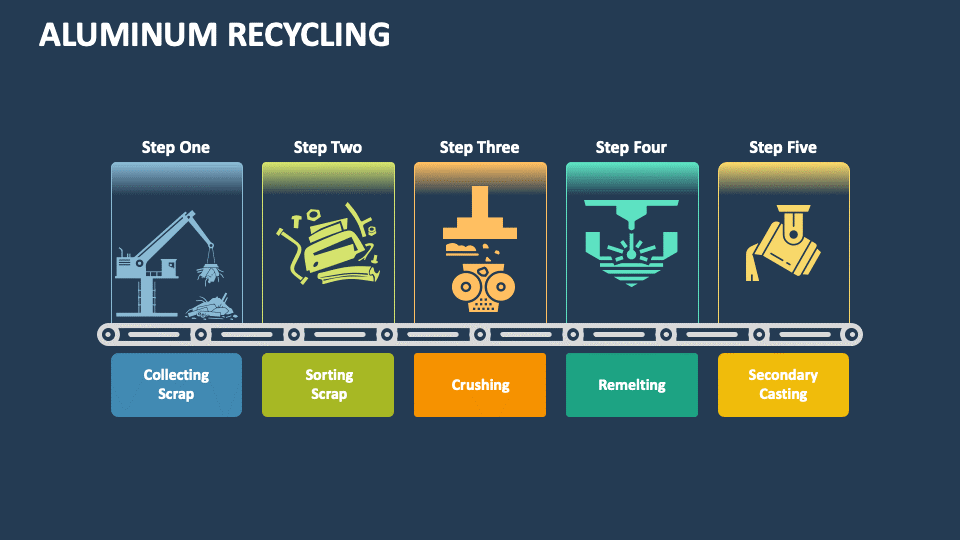

SUNO’s recycling process includes the following steps:

Step 1. Collecting Scrap.

As in all recycling operations, the first stage of aluminum recycling is collection. This stage involves the collection of used aluminum materials from many homes, factories, etc. Usually, the collected materials will include spray cans, drinking water cans, engine cover and synthetic aluminum . Note that some of them may have specialized rules regarding recycling.These materials are now collected through waste collection centres. Otherwise, it can be through individuals and professional businesses that are skilled in this.

Step 2: Sorting Scrap

The next stage is arrangement. The reality is that most piles will contain mixed materials. That is, steel cans will find their way into the pile. As such, it is important to distinguish these materials. This way both can pass the proper recycling process. As such, the collected materials will be sent to material recovery facilities. Here, they are sorted. Then they are also cleaned. Finally, they are compressed into bales. Note that this is after splitting.

Step 3: Crushing

The next stage is crushing the aluminum bales. And this happens in the processing plants where the packages are shipped. At this factory, the packages are put into an industrial shredder to cut the packages into small pieces. This stage is intended to ensure that the bales will easily lose all coating and paint. Usually, these paintings or coatings are for decoration and protection. However, they are only secondary. Also, crushing makes melting easier.

Step 4: Remelting

Here, the aluminum pile is now without aluminum and the coating is transferred to the kiln. The oven temperature stands at 7000C. Then other chemicals are also used inside the moult to ensure that it maintains the right composition. In turn, this causes all the residue – impurities – to float to the top. These impurities are then removed through a special scraper

Step 5: Secondary Casting.

Now the molten aluminum is fed into the furnace. Here, the aluminum stands until it is ready to be converted into ingots. After that, the oven keeps regularly pouring aluminum into the mold. Now, note that each block or ingot holds up to 1.6 million cans of the drink.

Recycling Products

ALUMINUM EXTRUSION

SYNTHETIC ALUMINUM

PISTON CAR

SYNTHETIC ALUMINUM

ENGINE COVER

DINK CANS

MOTORCYCLE RIMS

ALUMINUM NG

SHAPED ALUMINUM

WIRE

CAR RIM

CASTING PRODUCTS NG

ENGINE COVER

ALUMINUM BILLET

SHOCK ABSORBERS

ALUMINUM FOIL